Industrial Lighting

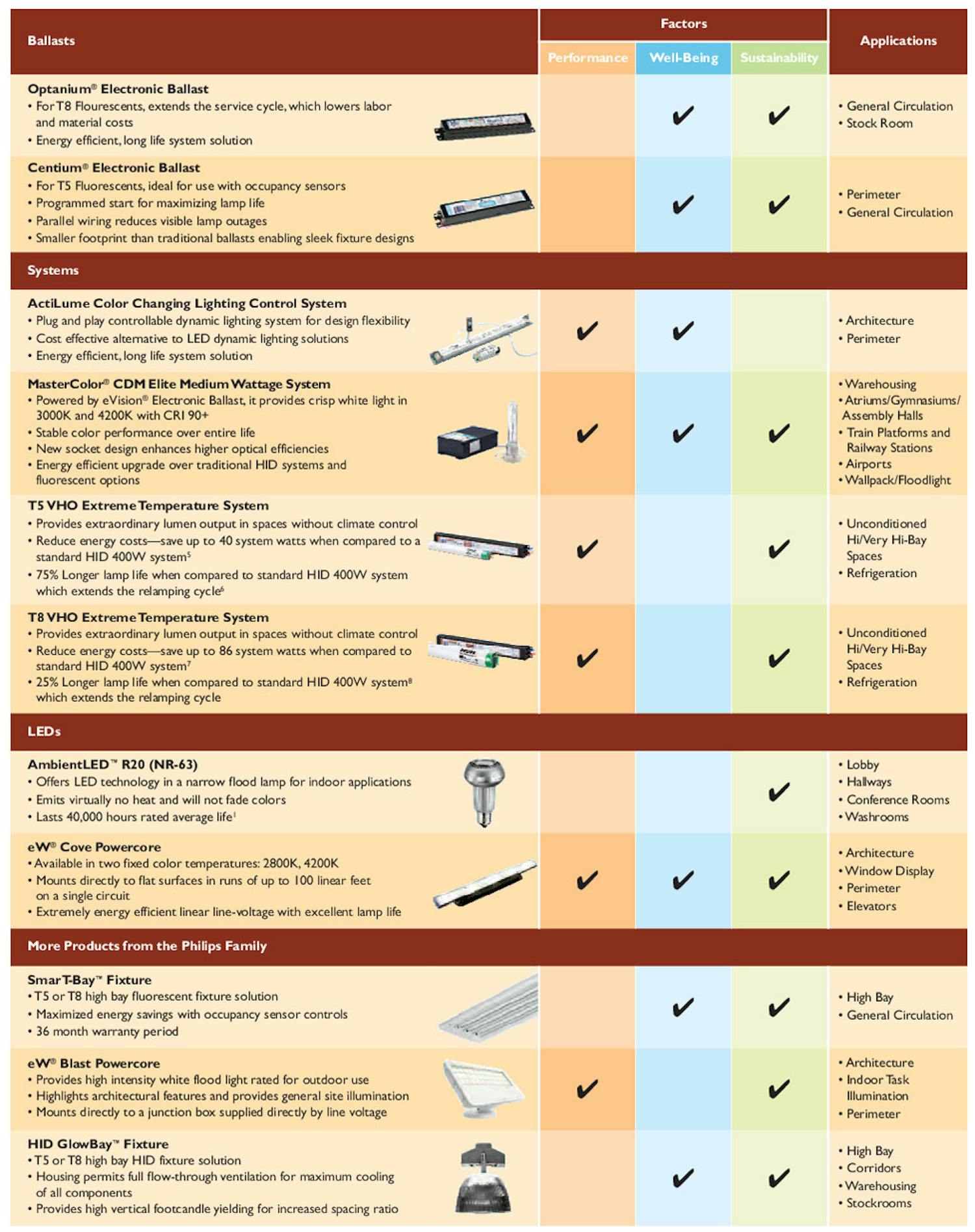

At Philips, we pride ourselves on producing tomorrow’s products today. Just like you, we value lighting solutions that are flexible enough to fit the needs of each unique user, while sustaining our environment.

In industrial settings where safety is a primary concern, many engineers acknowledge the significance of proper lighting. Adequate illumination is also a key factor in maintaining high worker productivity.

Artificial illumination is a costly commodity in some industrial plants. Improper application of lighting standards can result in excessive lighting that waste energy. By consulting the available literature, one can learn how to implement lighting modifications and energy conservation techniques that can save on lighting expenses.

A plant’s illumination system should meet certain minimum requirements in order to be cost-effective. Energy optimization, better productivity and safety are major goals to keep in mind when evaluating any lighting system. Significant increases in productivity can be achieved by lighting modifications that actually decrease the annual cost of electric illumination.

Among the major direct and indirect benefits adequate lighting provides are: improved visibility, upgraded aesthetics, better employee morale, reduced absenteeism, less eye fatigue and headaches, enhanced security, improved quality control and fewer rejects. All of these factors contribute to increased productivity and worker safety.